Finding Solutions for Your High-Temperature Needs!

Optimize Your Equipment with Expert Carbon Removal Services

Specializing in providing thorough carbon removal services to ensure your industrial equipment remains efficient, reliable, and safe. Carbon buildup can significantly impact equipment performance, leading to increased energy consumption, reduced efficiency, and even equipment failure. Our expert team uses advanced techniques to remove carbon deposits from all types of industrial equipment, ensuring optimal performance and extending the lifespan of your assets.

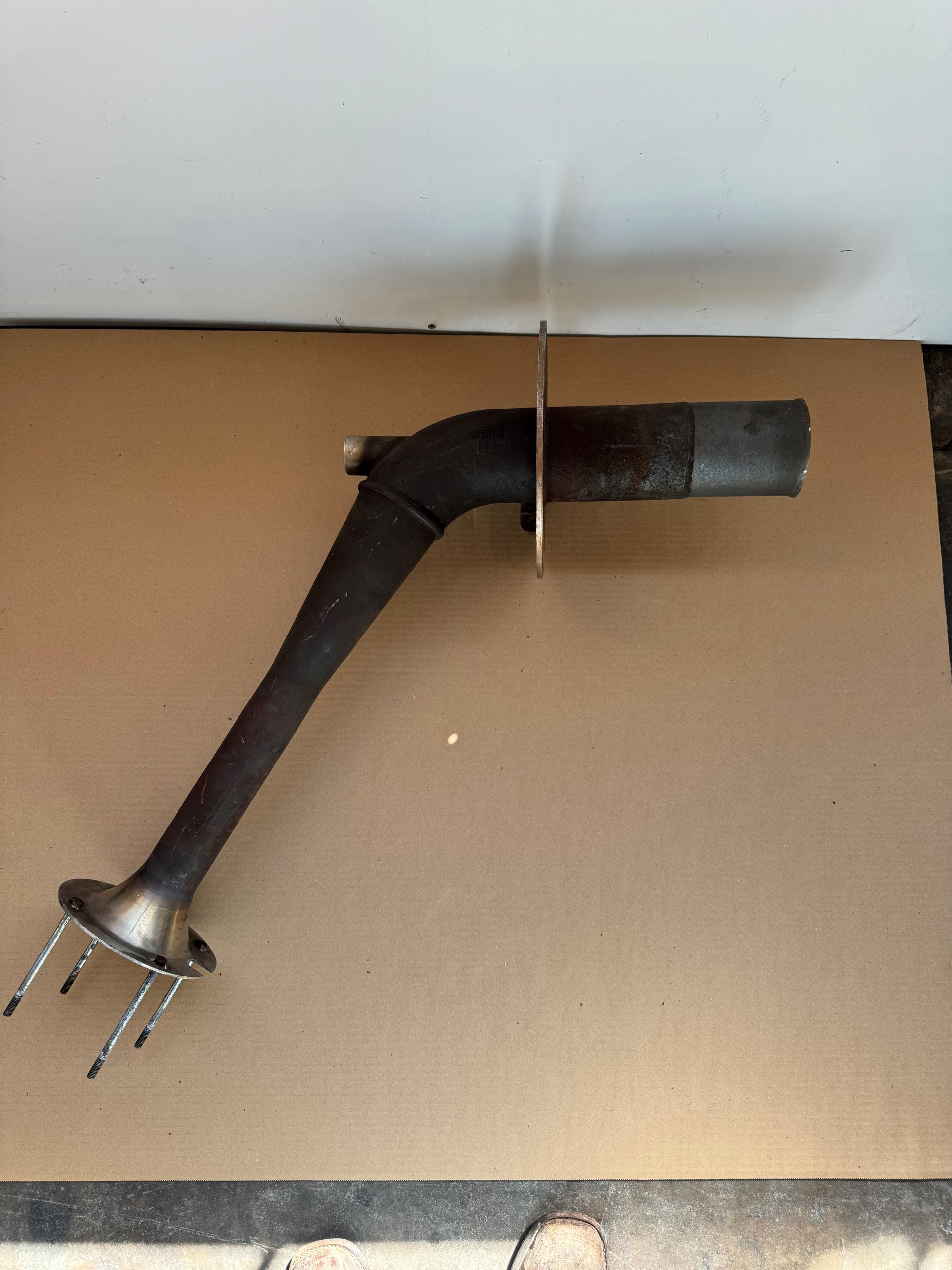

After

Why Choose Carbon Removal Services?

Regular carbon removal is crucial for maintaining the efficiency and longevity of your industrial equipment. Here are the key benefits of our carbon removal services:

Improved Efficiency: Removing carbon buildup restores your equipment to optimal operating conditions, reducing energy consumption and enhancing overall efficiency.

Extended Equipment Lifespan: Carbon deposits can cause wear and tear, leading to premature equipment failure. Regular carbon removal prevents this damage, extending the life of your equipment.

Reduced Maintenance Costs: By preventing carbon buildup, you can reduce the frequency and cost of repairs, saving money in the long run.

Enhanced Safety: Carbon buildup can create hot spots and increase the risk of equipment failure or fire. Our carbon removal services help maintain a safe operating environment.

Our Carbon Removal Process

We use a systematic approach to remove carbon deposits from your industrial equipment, ensuring thorough cleaning and optimal performance. Here's an overview of our carbon removal process:

Initial Assessment and Inspection

- Our process begins with a thorough assessment of your equipment to determine the extent of carbon buildup and identify any areas that require special attention. This inspection helps us choose the most effective carbon removal method for your specific needs.

Ultrasonic Cleaning for Deep Penetration

- For equipment with intricate parts or areas difficult to access, we use ultrasonic cleaning. This method involves submerging the equipment in a specially formulated cleaning solution and applying high-frequency sound waves to dislodge and remove carbon deposits, ensuring a deep clean without damaging the equipment.

Vapor Blasting for Precision Cleaning

- After ultrasonic cleaning, we employ vapor blasting to remove stubborn carbon deposits from the outer and inner surfaces of the equipment. This technique uses a mixture of water and abrasive materials to effectively clean without abrasive wear, ideal for maintaining the integrity of delicate components.

Chemical Carbon Removal (If Necessary)

- For particularly severe carbon buildup, we use specialized chemical treatments that dissolve carbon deposits without harming the equipment. This step is followed by a thorough rinse to ensure all chemicals are removed, leaving the equipment clean and ready for use.

Detailed Inspection and Maintenance

- Once the carbon removal is complete, we conduct a detailed inspection to ensure all carbon deposits have been removed and the equipment is in optimal condition. Any signs of damage or wear are addressed promptly to prevent future issues.

Final Quality Check and Documentation

- After all steps are completed, we perform a final quality check to ensure the equipment meets our high standards. We provide a detailed report of the services performed, including recommendations for future maintenance and carbon removal.

Our carbon removal services have helped numerous industrial clients restore their equipment's efficiency and reduce maintenance costs. By effectively removing carbon buildup, our clients have experienced significant improvements in performance and reliability.

Types of Carbon Removal Services We Offer

We offer a variety of carbon removal services tailored to meet the unique needs of different industries:

- Routine Carbon Cleaning: Regularly scheduled carbon removal to prevent buildup and maintain optimal equipment performance.

- Deep Carbon Cleaning: Intensive cleaning for equipment with severe carbon buildup that requires a more thorough approach.

- Preventive Maintenance Programs: Customized maintenance plans that include regular carbon removal to prevent buildup and extend equipment life.

Each service is customized to suit your specific requirements, ensuring the best possible results for your equipment.

Industries Served

Our carbon removal services are designed to meet the needs of various industries, including:

- Ethylene Plants: Prevent carbon buildup in burners and other critical components, ensuring efficient fuel combustion and reducing maintenance needs.

- Oil Refineries: Maintain optimal performance in high-temperature environments by removing carbon deposits from key equipment.

- Chemical Processing Facilities: Ensure reliable operation by preventing carbon buildup in equipment exposed to harsh chemicals and extreme conditions.

No matter your industry, our team has the expertise and equipment to provide the highest level of carbon removal service.

About Our Sister Company

As part of the Applied Refractory family, we work closely with a leader who manufactures high-temperature products for industrial clients. This partnership allows us to offer comprehensive solutions that include both high-quality refractory products and specialized carbon removal services, ensuring your equipment is protected and performing at its best.

Contact Us for a Quote

Ready to optimize your equipment with our carbon removal services? Contact us today for a detailed quote or to discuss your specific needs. Our team is here to help you maintain efficiency and reliability in your operations.

Phone: (281) 318-8286

Email:

jameselindsey@gmail.com

Frequently Asked Questions (FAQ)

How often should carbon removal be performed on industrial equipment?

The frequency of carbon removal depends on the equipment type, usage, and operating conditions. We recommend regular inspections and carbon removal as part of a preventive maintenance program to ensure optimal performance.

Can carbon removal damage my equipment?

Our carbon removal methods, including ultrasonic cleaning, vapor blasting, and chemical treatments, are designed to effectively remove carbon buildup without causing damage to the equipment.

Is on-site carbon removal available?

While our primary carbon removal services are performed in-house to ensure optimal results, we can assess on-site service needs on a case-by-case basis.

For more information, visit our FAQ page or contact us directly.

NAVIGATION

CONTACT US

Phone: 281-318-8286

Email: jameselindsey@gmail.com

Address: 2117 Dr Martin Luther King Jr Dr., Liberty, TX 77575

BUSINESS HOURS

- Mon - Fri

- -

- Sat - Sun

- Closed